- 3DGence Printers

- BigRep Printers

- WASP Printers

- Raise3D Printers

- Anisoprint Printers

- EnvisionTEC Printers

- Sintratec Printers

- 3DCeram Printers

- Nano Dimension Printers

- PostProcess Technologies

- Polyga Scanners

- Thor3D Scanners

- Raise3D Filaments

- 3DXTECH Filaments

- 3DGence Filaments

- BigRep Filaments

- EnvisionTEC Resins

- Polymer Powders

- Ceramic Pastes

Send us a Query

About EnvisionTEC

Founded in 2002 with its pioneering commercial DLP printing technology, EnvisionTEC now sells more than 40 printers based on six distinct technologies that build objects from digital design files. The company’s premium 3D printers serve a wide variety of medical, professional and industrial markets, and are valued for precision, surface quality, functionality and speed. EnvisionTEC’s intellectual property includes more than 100 pending and granted patents and 70 proprietary materials.

EnvisionTEC 3D technologies:

Robotic Additive Manufacturing (RAM): Through an exclusive strategic partnership with Viridis3D, EnvisionTEC is leading the way with robotic 3D printing, initially using binder jetting technology for sand casting in the foundry industry.

EnvisionTEC serves wide range of markets:

- Medical (dental & orthodontic, hearing aids, medical models & devices)

- Jewelry

- Manufacturing (prototypes, production parts, tools and jigs, injection moulding, consumer goods, aftermarket and replacement parts)

- Consumer goods

- Aerospace

- Automotive

- Foundries

- Education (scientific research, 3D visual aids, prototyping designs)

- Entertainment (stop motion animation, special effects, scale model production, CGI scenes, props and costumes)

- Toys

- Biofabrication (bone regeneration, drug release, cell/organ printing, soft tissue fabrication)

Desktop Family

Just because it sits on a desk doesn’t mean that desktop line 3D printers are like other cheap tabletop models. It’s not even close. EnvisionTEC desktop 3D printer family uses advanced Digital Light Processing (DLP) technology backed by more than a decade of development and exclusive patent-protected processes. The printers in this family are powerful tools used by thousands of professionals worldwide. That includes manufacturers of jewelry, hearing aids, dental models and appliances, medical devices, consumer goods, mechanical prototypes and more.

D4K Pro Dental

Properties:

- Build Envelope: 148 x 83 x 110 mm

- XY Resolution: up to 25 µm

- Z Resolution: up to 1 µm

- Dynamic Layer Thickness (Material Dependent): 15 – 150 µm

D4K Pro Jewelry

Properties:

- Build Envelope: 148 x 83 x 110 mm

- XY Resolution: up to 25 µm

- Z Resolution: up to 1 µm

- Dynamic Layer Thickness (Material Dependent): 15 – 150 µm

Micro Plus Desktop Family system properties:

- Technology: DLP

- Light Source: Industrial UV LED

- Changeover between materials is quick and easy with no waste

- Plug and play with an easy to use software interface

- Very few moving parts guarantees a strong and reliable production system

- Touchscreen and embedded PC with Wi-Fi capability add ease to the user interface

Micro Plus HD

The Micro Plus HD can produce small, premium components requiring a high level of precision, making it perfect for designers, shops and small jewelry businesses. It is able to build parts with excellent detail and surface finish for multiple industries: Entertainment, Jewelry, Dental, Consumer Goods, Education, Medical Devices, Manufacturing and etc.

Properties:

- Build Envelope: 45 x 28 x 100 mm

- XY Resolution: 30 µm

- Dynamic Z Resolution (Material dependent): 25 – 75 µm

Vida Desktop Family system properties:

- Technology: DLP

- Light Source: Industrial UV LED

- Compatible with leading dental, hearing aid, jewelry and other professional design software

- Any STL file of a model designed from an impression or a scanner can be printed

- Capable of printing a wide variety of dental, orthodontic, manufacturing, jewerly and hearing applications

- Changeover between materials is quick and easy with no waste

- Touchscreen and Wi-Fi capability enhance the user interface

- Very few moving parts guarantees a strong and reliable production system

Vida Desktop

Properties:

- Build Envelope: 140 x 79 x 100 mm

- XY Resolution: 73 µm

- Dynamic Z Resolution (Material dependent): 25 to 150 µm

Micro Plus Advantage

Properties:

- Build Envelope: 65 x 40 x 100 mm

- XY Resolution: 60 µm

- Dynamic Z Resolution (Material dependent): 25 – 75 µm

Vida HD

The Vida HD is a low cost, open architecture, easy to maintain and user friendly DLP technology 3D printer. The Vida HD boasts a high resolution projector with custom UV optics and is especially well-suited for dental and jewelry applications. The 50 μm resolution of the Vida HD allows for outstanding surface finish and detail while the generous build size adds efficiency to dental, hearing aid and custom jewelry production.

Properties:

- Build Envelope: 96 x 54 x 100 mm

- XY Resolution: 50 µm

- Dynamic Z Resolution (Material dependent): 25 to 150 µm

Micro Plus XL

Properties:

- Build Envelope: 120 x 74 x 85 mm

- XY Resolution: 82 µm in X and 105 µm in Y

- Dynamic Voxel Resolution in Z (User adjustable and material dependent): 25 – 75 µm

Vida HD C&B

Properties:

- Build Envelope: 90 x 50 x 100 mm

- XY Resolution: 35 µm

- Dynamic Z Resolution (Material dependent): 25 to 150 µm

- Compatible with 3Shape, Orchestrate 3D, Dental Wings and Exocad design software

- Capable of precise crown and bridge waxups

cDLM Family

EnvisionTEC launched Continuous Digital Light Manufacturing (cDLM) technology in early 2016 with the Micro Plus cDLM. A twist on their DLP technology, this process allows for continuous motion of the build plate to deliver exceptional build speeds.

- Technology: cDLM

- Light Source: Industrial UV LED

- Compatible with all design software capable of outputting an STL file

- Changeover between materials is quick and easy with no waste

- Plug and play with an easy to use software interface

- Very few moving parts guarantees a strong and reliable production system

Micro Plus cDLM

Properties:

- Build Envelope: 45 x 28 x 75 mm

- Pixel Size in X: 39.8 µm

- Pixel Size in Y: 31.25 µm

- Dynamic Resolution in Z (material dependent): 15μm to 150 μm

Vida HD cDLM

Properties:

- Build Envelope: 90 x 50 x 100 mm

- XY Resolution: 50 µm

- Dynamic Resolution in Z (material dependent): 15 to 150 μm

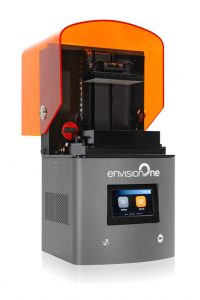

Envision One cDLM Mechanical

EnvisionTEC One cDLM is the largest, most advanced desktop 3D printer ever created. It is bigger, faster, easier to use and more innovative than all the other 3D printers on the market. EnvisionTEC delivers an end to end solution including design software parameter optimization to deliver accurate parts every time with minimal supports. Perfect for a wide variety of 3D printing applications, the Envision One cDLM is capable of printing up to 80 mm/hour, material dependant.

Properties:

- Build Envelope: 180 x 101 x 175 mm

- Build Speed: Up to 80 mm/hour (material dependent)

- Native XY Resolution: 93 µm

- XY Resolution with Contour Gray Scaling: 60 µm

- Dynamic Resolution in Z (material dependent): 50 µm to 150 µm

Envision One cDLM Dental

Properties:

- Build Envelope: 180 x 101 x 85 mm

- Build Speed: Up to 80 mm/hour (material dependent)

- Native XY Resolution: 93 µm

- XY Resolution with Contour Gray Scaling: 60 µm

- Dynamic Resolution in Z (material dependent): 50 µm to 150 µm

Envision One cDLM HT

Properties:

- Build Envelope: 180 x 101 x 175 mm

- XL Version also Available: 180 x 101 x 330 mm

- Build Speed: Up to 120 mm/hour (material dependent)

- Native XY Resolution: 93 µm

- XY Resolution with Contour Gray Scaling: 60 µm

- Dynamic Resolution in Z (material dependent): 50 µm to 150 µm

Perfactory Family

Designed for real production, EnvisionTEC “personal factory” line of 3D printers uses exclusive DLP technology and offers the ability to run lights-out production. First launched in 2002, the Perfactory isn’t just an icon in the 3D printing world – the printer on wheels — it’s a trusted and reliable one. We have long-time users who call just to say hello, and let us know that they’ve never had to ring us up for service.

Applications: Aerospace, Entertainment, Automotive, Jewelry, Dental, Hearing Aid, Consumer Goods, Education, Medical Devices, Manufacturing, Orthodontic and etc

- Economic material use with no vat

- Minimized components make the system user serviceable

- Designed to run 24/7 in a production environment

- Delivered with all relevant software to enable automatic support generation and perfect model production

- Material changeover can be done quickly and easily

Xtreme 8K DLP

The Xtreme 8K DLP uses dual 4K projector DLP technology to quickly 3D print highly accurate parts. With a large selection of materials, you will be able to produce high-quality end-use parts for a variety of applications, including industrial and medical items. A heated material vat allows for additional materials with highly desirable properties.

Properties:

- Build Envelope: 406.8 x 442.5 x 395 mm

- XY Voxel Size With ERM and Pixel Tuning: 100 µm

- Dynamic Voxel Resolution in Z (material dependent): 100 – 150 μm

P4K 35 or P4K 62 or P4K 75 or P4K 90

Properties:

- Build Envelope: 90 x 56 x 180 mm or 160 x 100 x 180 mm or 192 x 120 x 180 mm or 230 x 143.75 x 180 mm

- Native Pixel Size XY: 35 µm or 62 µm or 75 µm or 90 µm

- Pixel Size With ERM: 23 or 40 or 49 or 59

- Dynamic Voxel Resolution in Z (material dependent): 25 – 150 μm

- Projector Resolution: 2560 x 1600 (WZXGA)

3SP Family

So, you need big, heavy-duty parts? EnvisionTEC got you covered with their 3SP technology, which uses a UV laser to scan, spin and selectively photocure resins into large, durable parts up to 95 liters. You do not need to sacrifice accuracy or surface finish to make big 3D objects with 3SP.

EnvisionTEC 3SP printers can build a wide range of manufacturing objects, from functional gears, valves and pumps to fasteners, jigs, fixtures or end effectors. But it’s also being used for mass customized production in the dental industry, where their printers are known for accuracy and an unparalleled smooth surface finish that minimizes post-processing. It can also 3D print tooling for thermoplastic injection moulding.

Ultra 3SP and 3SP HD

Properties:

- Build Envelope: 266 x 175 x 193 mm

- XY Resolution: 50 / 100 µm

- Dynamic Voxel Resolution in Z (material dependent): 50 – 100 μm

- A single material is used for both build and support

- Easily removable, partially cured perforated supports

- Very few moving parts make the system user-serviceable

- Office friendly plug-and-play operation with a built-in touch screen

- Extremely reliable system utilizing 3SP (Scan, Spin, and Selectively Photocure) technology

- Low part cost due to minimal material waste

- Produce everything from concept models to functional parts

- Layerless technology with no stair stepping on inner and outer surfaces

- Quiet operation

Ultra 3SP Ortho

Properties:

- Build Envelope: 266 x 175 x 76.2 mm

- XY Resolution: 100 µm

- Dynamic Voxel Resolution in Z (material dependent): 50 – 100 μm

- Simple user interface with built-in touch screen

- Very few moving parts and minimal consumable components guarantee a strong and reliable system

- Office friendly plug-and-play operation with a built-in touch screen

- Low part cost due to minimal material waste

- Remote notification when job is complete

- Lowest operational costs in its class

3Dent 3SP

Properties:

- Build Envelope: 266 x 175 x 76 mm

- XY Resolution: 50 µm

- Dynamic Voxel Resolution in Z (material dependent): 50 – 100 μm

- Simple user interface with built-in touch screen

- Very few moving parts and minimal consumable components guarantee a strong and reliable system

- Lowest operating cost in its class

- Low part cost due to minimal material waste

- Office friendly plug and play operation with a built-in touch screen

- Remote notification when job is complete

Vector 3SP

Properties:

- Build Envelope: 300 x 200 x 275 mm

- XY Resolution: 100 µm

- Dynamic Voxel Resolution in Z (material dependent): 50 – 100 μm

Vector HD 3SP

Properties:

- Build Envelope: 300 x 175 x 275 mm

- XY Resolution: 50 µm

- Dynamic Voxel Resolution in Z (material dependent): 50 – 100 μm

Vector 3SP Ortho

Properties:

- Build Envelope: 300 x 200 x 70 mm

- XY Resolution: 100 µm

- Dynamic Voxel Resolution in Z (material dependent): 50 – 100 μm

- A single material is used for both build and easily removable, partially cured perforated supports

- Very few moving parts make the system user serviceable

- Low part cost due to minimal material waste

- Can connect directly to a PC workstation or be integrated into a network for pre-processing of the job files and for remote monitoring

- The system has a stand-alone PC with a 22” touchscreen monitor

Xtreme 3SP

Properties:

- Build Envelope: 254 x 362 x 330 mm

- XY Resolution: 100 µm

- Dynamic Voxel Resolution in Z (material dependent): 50 – 100 μm

- A single material is used for both build and easily removable, partially cured perforated supports

- Very few moving parts make the system user-serviceable

- Low part cost due to minimal material waste

- Produce everything from concept models to functional parts

- Can connect directly to a PC workstation or be integrated into a network for pre-processing of the job files and for remote monitoring

- The system has a stand-alone PC, which allows it to work independently from the pre-processing workstation

Xede 3SP

Properties:

- Build Envelope: 457 x 457 x 457 mm

- XY Resolution: 100 µm

- Accuracy: +/-150 µm

- Dynamic Voxel Resolution in Z (material dependent): 50 – 100 μm

- A single material is used for both build and easily removable, partially cured perforated supports

- Very few moving parts make the system user-serviceable

- Low part cost due to minimal material waste

- Produce everything from concept models to functional parts

- Connect directly to a PC workstation or be integrated into a network for pre-processing of the job files and for remote monitoring

- The stand-alone PC allows for working independently from pre-processing workstation

Accessories

PCA 2000 Parts Curing Apparatus

- Solution for post-curing parts that have been 3D printed using cDLM or DLP technologies

- Two predefined settings for standard use to finalize small and large jobs

- Custom settings option to create a customized curing program

- Internal Chamber Dimensions: 200 x 200 x 190 mm

PWA 2000 Parts Washing Apparatus

- Convenient tool to assist in cleaning any uncured resin from 3D printed models

- Three washing programs

- Washing Compartment Dimensions: 145 x 145 x 105 mm

Otoflash Post Curing Light Pulsing Unit

- Light polymerization chamber for the hardening / curing of light curing resins for jewellery, dental, and otoplastic applications

- Inner Chamber Dimensions: 120 x 120 x 50 mm

PCA 100 Post Curing Apparatus

- Post Curing Apparatus for the final hardening and strengthening of photopolymer parts that were 3D printed

- Ideal for applications in jewellery, dental, and the hearing aid industries

- Useable Inner Chamber Dimensions: 108 x 108 x 70 mm

UVCA 2000 UV Curing Apparatus

- The UV Curing Apparatus (UVCA 2000) for ULTRA 3SP and Xtreme 3SP includes 12 power compact UV fluorescent lamps for the post-processing of UV sensitive curing resins for industrial, jewellery, dental, medical, and other applications

- Inner Chamber Dimensions: 457 x 457 x 355 mm

Ultrasonic Bath

- Ultrasonic bath to clean your printed parts with isopropanol

Basement Rack

- Basement rack (Big or Small) to store the basements which are not used at the moment