- 3DGence Printers

- BigRep Printers

- WASP Printers

- Raise3D Printers

- Anisoprint Printers

- EnvisionTEC Printers

- Sintratec Printers

- 3DCeram Printers

- Nano Dimension Printers

- PostProcess Technologies

- Polyga Scanners

- Thor3D Scanners

- Raise3D Filaments

- 3DXTECH Filaments

- 3DGence Filaments

- BigRep Filaments

- EnvisionTEC Resins

- Polymer Powders

- Ceramic Pastes

Send us a Query

About Anisoprint

Anisoprint has developed anisoprinting — a technology for design and production of optimal composites through continuous fiber 3D printing.

Get the full potential of composites with the benefits of Anisoprint open system:

- Strong and lightweight

30 times stronger than plastic

7 times lighter than steel

2 times stronger and lighter than aluminium

- Optimal

Printing lattice structures: the most optimal shape for composites

Getting maximum strength spending minimum material

- Flexible

Custom trajectories of fiber laying

Freedom in materials choice: any plastic as a matrix

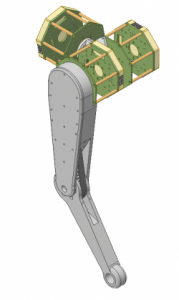

Composer A4 & A3

Desktop 3D printers Composer A3 & A4 for manufacturing optimized composite structures through continuous fiber 3D printing.

Continuous fiber reinforced composites with up to 900 MPa strength while low weight and perfect surface quality: available with the touch of a button.

Main Features:

Printing technology: Composite Fiber Co-extrusion (CFC) and Fused Filament Fabrication (FFF)

2 sizes: A4 297×210×147 mm & A3 420×297×210 mm build area

- Layer thickness: 60 µm

- Printing reinforced lattice structures: lower weight, price and production time

- Open material system — any plastic with processing temperature up to 270°C as a matrix (PETG, ABS, PC, PLA, PA, etc.)

- Complete control over fiber path generation

- Compared to analogues: Lower porosity — higher strength / 30-50% lower material printing costs

PROM IS 500

Industrial anisoprinting – easier, faster and cheaper manufacturing process with high-strength parts from continuous fiber reinforced composite.

Continuous fiber reinforced composites with up to 900 MPa strength while low weight and perfect surface quality: available with the touch of a button.

Main Features:

- Up to 4 interchangeable print heads: Composite Fiber Co-extrusion (CFC) and Fused Filament Fabrication (FFF)

- Large build volume: 600x420x300 mm

- Layer thickness, min: 60 µm

- Heated chamber temperature: up to 160°C

- High temperature plastics (up to 400°C) as a matrix (PEEK, PEI, PC, PA, etc.)

- Automatic calibration system

- Industrial CNC, industrial standards: reliability, repeatability, precision and safety

- Open system: made for 24/7 run in a factory environment

- Enclosure – stable temperature during the printing process

- Material flow control system – sensors allows the printer to control filament flow

Application cases: