- 3DGence Printers

- BigRep Printers

- WASP Printers

- Raise3D Printers

- Anisoprint Printers

- EnvisionTEC Printers

- Sintratec Printers

- 3DCeram Printers

- Nano Dimension Printers

- PostProcess Technologies

- Polyga Scanners

- Thor3D Scanners

- Raise3D Filaments

- 3DXTECH Filaments

- 3DGence Filaments

- BigRep Filaments

- EnvisionTEC Resins

- Polymer Powders

- Ceramic Pastes

Send us a Query

About BigRep

BigRep develops the world’s largest serial production 3D printers, creating the industry benchmark for large-format additive manufacturing. Their award-winning, German-engineered machines are establishing new standards in speed, reliability and efficiency.

From furniture to vehicles and robotics – everything is possible. They want you to envision everything from human scale robot parts, sculptural artworks in all their full-dimensional glory, and dream the impossible world-changing designs of tomorrow while enabling you to print them today using one of large format Fused Filament Fabrication (FFF) 3D printers.

Application possibilities limited only by your imagination:

- Production aids

- Prototypes in product development

- End-use parts and products

- Jigs and fixtures

- Casting patterns

- Construction moulds

- Spare parts

- Consumer products

- Arts

BigRep ONE

The BigRep ONE was created to make industrial 3D printing of large-scale objects as easy and affordable as possible. German-engineered for better quality, higher speed, and increased safety, when using room temperature materials. The BigRep ONE won the German Design Award 2016 and continues to be used in a diverse range of industries and applications.

With a build volume of more than one cubic meter and the open format modular print heads it provides the ideal 3D printer for manufacturing large-scale objects. The BigRep ONE works perfectly in automotive or aerospace industries, as well as entertainment, design or concept modelling. It brings the large-scale additive manufacturing on more affordable level in prototyping or designing. The German-engineered BigRep ONE is built to be a workhorse 3D printer that innovators can rely on.

Specifications

Specifications | Values |

|---|---|

Build volume | x 1005 y 1005 z 1005 (mm) |

Layer heights | 0,3 mm, 0,6 mm, 1,0 mm |

Max. speed | Max. acceleration | 500 mm/s | 400 mm/s² |

Extruder | Fiber-Ready Power Extruder (PEX)

Interchangeable hotends with fiber-ready 0.6 mm and 1 .0 mm nozzles and a high-flow 2.0 mm nozzle |

Printing technology | FFF – Fused-Filament-Fabrication (FDM) |

Certified BigRep materials | HI-TEMP, HI-TEMP CF, PETG, PLA, PLX, PRO HT, TPU 98A

Open for 3rd party materials |

Support materials | BVOH

Other filaments upon request |

Print bed temperature | Max. 80 °C |

Printer weight | Approx. 460 kg |

Size | x 1850 y 2250 z 1725 (mm) |

Power | 208 V – 240 V, 16 A, 50 / 60 Hz |

Safety certifications | CE approved |

Benefits & features:

- Open & safe frame construction

- Modular and independent print heads

- Semi-automatic print bed levelling

- Large build volume of 1005 mm x 1005 mm x 1005 mm.

- Spacious and flexible spool holder

- Easy and intuitive graphical user interface

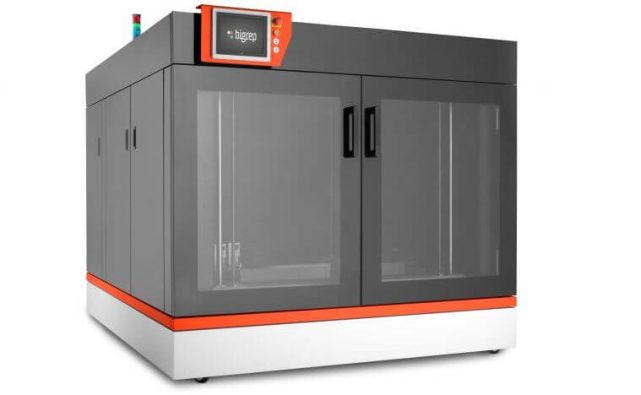

BigRep STUDIO G2

Explore new frontiers of large-format industrial printing with the new and improved BigRep STUDIO G2 made for abrasive and engineering-grade materials. With a fast-heating print bed and temperature-controlled filament chamber this high-resolution large-print workhorse produces incredible results with high-quality materials.

The enclosed print envelope maintains a controlled temperature enabling continuous printing of large-format objects with nylon and other engineering-grade materials. As winner of the prestigious 2018 German Innovation Award the BigRep STUDIO G2 is the ideal German-engineered 3D printer, proven for all types of industry professionals to bring their innovative designs to life.

Specifications

Specifications | Values |

|---|---|

Build volume | x 1000 y 500 z 500 (mm) |

Layer height resolution | 0.1 – 0.6 (mm) |

Acceleration | Up to 600 mm/s |

Extruder | Dual extruder Equipped with two hot ends (0.6 or 1.0 mm diameter) |

Printing technology | Fused Filament Fabrication (FFF) |

Compatible BigRep Materials | ASA, HI-TEMP, HI-TEMP CF, PETG, PLA, PLX, PRO HT, TPU 98A

Open for 3rd party materials |

Printbed temperature | Max. 100 °C |

Printer weight | Approx. 550 kg |

Size | x 1715 y 1170 z 1765 (mm) |

Power | 208 V – 240 V, 16 A, 50/60 Hz |

Safety certifications | CE approved |

Benefits & features:

- The best-in-class print heads for engineering grade materials

- The insulated build envelope

- The heated filament chamber for temperature control

- Easy & intuitive new Slicer

- The fast-heating Print Bed for optimal printing temperatures

- Massive build volume of 500 mm x 1000 mm x 500 mm

BigRep PRO

The BigRep PRO is a German-engineered, large-format additive manufacturing system for industrial applications. The BigRep PRO is a machine that prints with engineering-grade materials to ensure users can manufacture the applications they need, in large scale. The PRO is an industrial 3D printer that responds to market demand and is embedded with new Metering Extruder Technology (MXT®), an enclosed build chamber and temperature-controlled filament chambers for big, impressive, prints.

Specifications

Specifications | Values |

|---|---|

Build volume | x 1020 y 970 z 985 (mm) fully enclosed |

Materials | ASA, HI-TEMP, HI-TEMP CF, PETG, PLA, PLX, PA12 CF, PRO HT, TPU 98A, and open for 3rd party materials |

Speed | Acceleration (XY) | Max. 600 mm/s | Max. 5 000 mm/s² |

Support materials | BVOH.

Open for 3rd party materials |

Extruders | Two Fiber-Ready PRO ACE Extruders.

Interchangeable hotend with fiber-ready

0.6 mm and 1 mm nozzle. |

Layer Height Resolution | 0.3 mm – 0.6 mm. Other layer heights supported through slicer software. |

Material Storage | Sealed Filament Chamber supporting up to 8 kg spools |

Print Bed Temperature | Max. 100 °C |

Safety Certification | CE, and EC Machinery Directive 2006/42/EC Compliant |

Benefits & features:

- An insulated enclosed metal frame

- Insulated filament cabinet for industrial material compatibility

- Metering extruder technology (MXT®) with exceptional speed and precision

- Heated print-bed with semi-automatic levelling

- State-of-the-art Bosch CNC motion- control system

- Large build volume of 1020 mm x 970 mm x 985 mm